A successful shower installation requires careful planning and a lot of work. In most cases, you will need to do three types of tasks: framing walls, installing the plumbing, and finishing walls.

Preparation

Firstly, you must decide on the type of shower that you wish to install. It is important to ascertain whether the chosen shower is capable of coping with certain systems and can regulate a safe level of water through the boiler. Most shower units nowadays are designed to be flexible to different water pressures (such as stored hot water and cold mains).

It is also important to take into account the water pressure and the planning of the piping and drainage for the shower

Different Types of Shower Units

Push-on Mixer: The hose and spray parts of the push-on mixer shower unit can be connected to the bath tap as per your requirement, and the water temperature can be adjusted via the taps. Push-on mixers are cheap and extremely simple to install. However, although the hose connection is simple, it is easily dislodged. Additionally, it is inconvenient to adjust the temperature.

Bath/Shower Mixer: The hose and spray of this type of shower are combined with a bath mixer tap, and the temperature can be adjusted through the bath taps. It is a very cheap option and no extra plumbing is involved. However, the bath/shower mixers also suffer from inconvenient temperature control options.

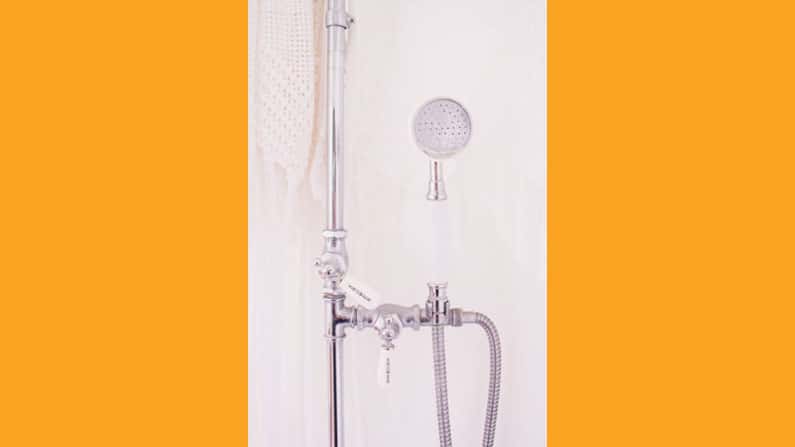

Manual Mixer: The hose and spray of a manual mixer shower unit are a part of the wall unit and the hot and cold water supplies are connected to a single valve The temperature and pressure of the water are controlled through either one or a variety of knobs (in more expensive showers). Although temperature control is much easier in manual mixer types, they are more expensive than the previously mentioned mixers. They also require additional plumbing of hot and cold water supply pipes.

Thermostatic Mixer: The hose and spray of this shower type are a part of the wall unit and the hot and cold water supplies are connected to a single valve here too. It is complete with a built-in stabiliser to self-adjust the water temperature and to prevent it from becoming too hot. One of the biggest advantages of a thermostatic mixer shower type includes convenient temperature control. However, it is the most expensive of the different mixer options.

Power Shower: A power shower is a single unit containing a powerful electric pump that is capable of altering both the water pressure and temperature. This type of shower can be fitted if there is water supply from a cold water cistern and a hot water cylinder. A power shower makes the adjustment of both pressure and temperature easy. On the other hand, it is unsuitable for water heated directly by the shower or where the water is supplied by a combination boiler under mains pressure.

Electric Shower: An electric shower is plumbed into a mains cold water supply and it heats the water electrically. It is important to note that for this shower type to be installed, the mains pressure needs to be at least 0.7kg/sq cm (10lb/sq in). The unit allows the temperature and pressure to be adjusted via a knob. Models with temperature stabilisers are better as they remain unaffected by other taps elsewhere in use within the household. A major drawback of electric showers is that the control knob only allows for the option of high temperatures at less pressure, or lower temperatures at a greater pressure. This is problematic in the winter season when the spray is often weak and the mains water is colder. However, this problem is tackled in some models which are available with a winter/summer setting.

Method

Depending on the type of shower you wish to install, the shower head must either be fitted in order to avoid its contact with the water in the bath below or the base tray, or it must have a check valve.

Before starting, it is advisable to mark the positions of the shower head and control, and to plan the pipe-work involved. Additionally, the drainage system to remove the waste water will need to be planned. Both positions of the cable route and the shower switch will also need to be considered if an instantaneous or electric shower unit is being installed.

Use the instruction guide provided with the shower unit to fit the shower control.

Before fitting the pipes that will supply the water to the shower system, it is important to cut off the water supply. In order to protect the pipes, they should be given a waterproof covering and also fitted with isolating valves. The pipes can then be buried into the wall and plastered over to neaten the overall look.

Fit the base tray, shower head, and fittings.

Connect the main shower control to the pipes that will be supplying the water (This may require a female screw thread adapter).

Reconnect the water supply and test the pipes for any leaks, as some may need tightening.

If you are installing an electrical shower, remember to switch off the electricity supply before making any electrical connections. Once these connections have been made (there should be guidance within the instruction manual), the power supply can be switched back on.

Adjusting Water Pressure to Suit Your Shower

The cold water reservoir can be lifted to a greater height (sometimes as little as 150mm (6inches)) by fitting a strong wooden support beneath it – possibly composed of struts and blockboards. If you choose this option, the main and distribution pipes will also have to be raised to meet the new height of the reservoir.

Alternatively, a booster pump (a single pump or a dual/twin pump) can be fitted. Whichever type is chosen, it must be connected into the power supply in order to operate.

Piping and Drainage

It is best to use 15mm diameter supply pipes, and make the runs to the shower as short and straight as possible so as to maintain maximum pressure and minimise heat loss. Additionally, by minimising the use of elbows for pipe corners, you can decrease the resistance in the flow of the water supply. You can achieve this by bending the pipes instead.

Most Common Mistakes

# Violating or ignoring local code restrictions.

# Using pipes that are too small.

# Attaching copper to galvanized without using a brass or dielectric fitting between the two.

# Not using tape or pipe compound at threaded joints.

# Not leveling your fixtures when installing them.

# Not installing an air gap filling for fixtures.

# Cutting supply stub outs too short to install the shutoff valves onto after the finished wall is in place.

# Not properly aligning tubing into fittings or stop valves. (Forcing the nut onto the compression ring at an angle when the tubing is at an angle will cause a leak.)

# When turning the water back on in your home, always run the outside hose valve or flush your toilets to bleed dirt and air from the lines. This debris can cause problems in your sink faucets and other plumbing trim.

Thank you for taking the time with me to learn more about what Mr. Done Right, the handyman / contractor does for you.

Sincerely,

Nathaniel Peterson

(AKA) Mr. Done Right

For more information on handyman or contractor work in the greater Austin area (or beyond), please contact your premiere handyman, Nathaniel Peterson, AKA Mr. Done Right Handyman Contractor of Austin, because Mr. Done Right ensures any repairs and/or remodels get Done Right the first time! Call us now for a free estimate! 512-659-8931

* Click here to protect your privacy and the safety of your children on the Internet.

Online Marketing Powered by www.OnlineMarketingExperts.agency

Recent Comments